Welcome to our company

Heat treatment

Our extensive experience and ongoing research and development efforts have created special heat treatment solutions that are unique worldwide. These systems are created by our organization and are operated via contemporary computers.

Annealing

- The rolls are exposed to elevated temperatures for a long time and cooled slowly at room temperature; after furnace cooling, this results in small particles of pro eutectoid ferrite and a small coarse lamellar pearlite area.

- Prolonged time at elevated temperatures will completely break up the pearlite structure and cementite network.

- Annealing is carried out to relieve stress and increase softness, ductility & toughness.

- Improves machinability.

- Improves electrical/magnetic properties.

Hardening

- Martensite microstructure formation is obtained by rapidly quenching the rolls before the pearlite formation occurs.

- Desired hardness is achieved by regulating the range of temperature and reducing the time between the end of heating and the start of quenching.

- Quenched martensite is too brittle; hence it requires tempering.

Tempering

The formation of martensite leaves high residual stress in steel. Therefore, tempering is required. In this process, the rolls are heated below the critical temperature and then air-cooled. The temperature varies according to the hardness that needs to be reduced. It decreases brittleness and increases toughness.

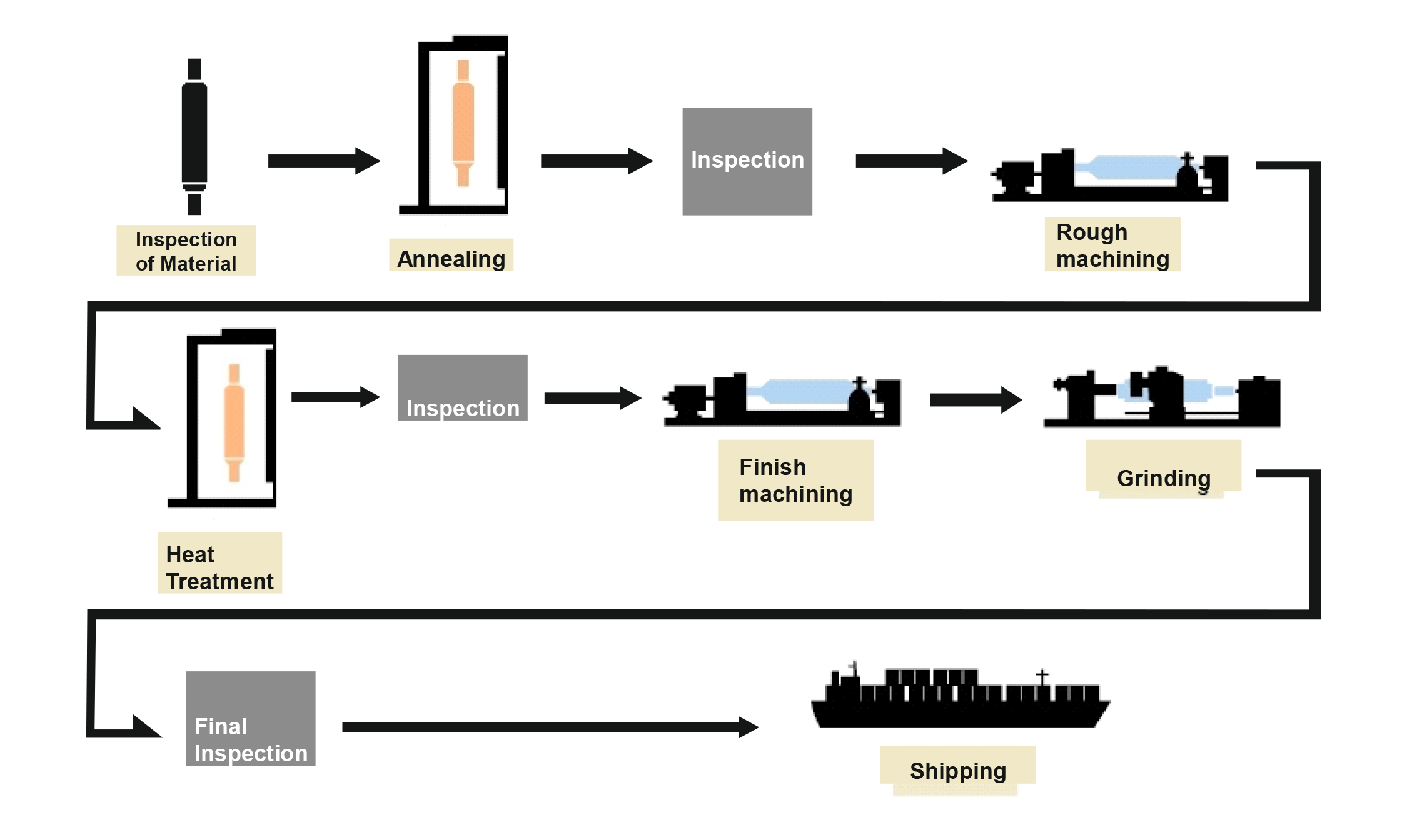

Production Process

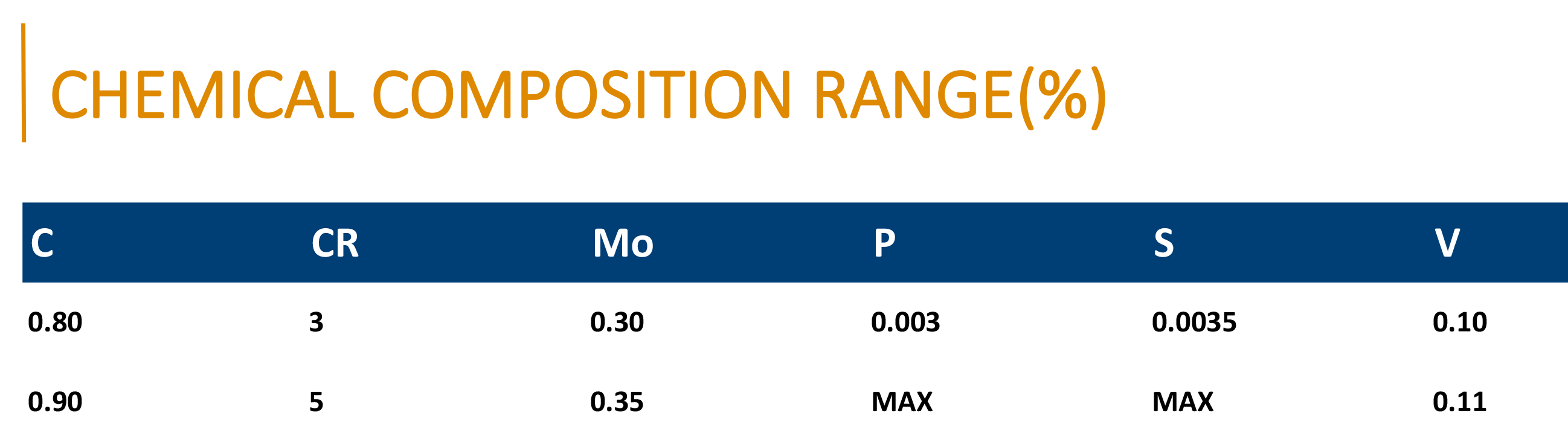

We buy the forged blanks from reputable vendors following customer drawings. The forged steels with 3-5% CrMo content produce rolls.

Annealing

The material then underwent spheroidizing annealing to obtain a rounded form of carbide in a ferritic matrix. It helps in improving machinability.

Hardening and Tempering

- The steel is heated above the critical temperature and rapidly cooled down. The resultant structures are called martensite; the maximum achievable hardness is around Rockwell C 65-66 with a depth of up to 50mm.

- The martensite structure is too brittle for production use; hence immediate tempering is done to improve flexibility and toughness.

Machining

- Currently, we operate 40 lathes, 6 grinders, 5 shapers, and 2 millings. These include some semi-CNC too. Highly skilled professionals operate all these machines.

- Rolls weighing 15 tonnes, with diameters up to 1,100 millimeters and total lengths up to 4,500 millimeters, can be manufactured using our high-performance lathes, milling, and grinding machines.

Quality Control

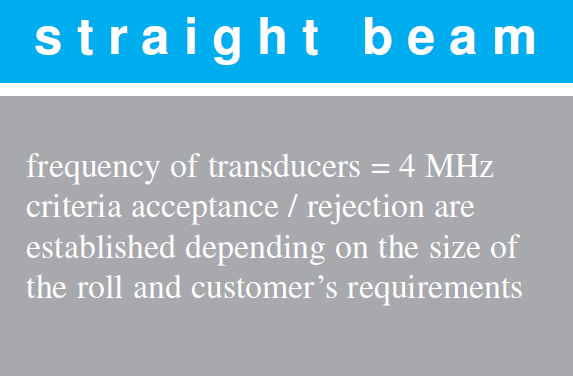

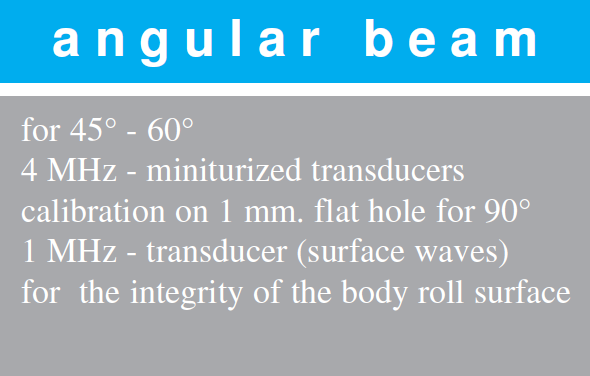

Ultrasonic inspection

The tests are performed both with:

- NDT to detect even minor cracks or defects in the rolls

- Test for hardness and depth of hardness

- Measurement and tolerance test